Go directly to

Nuclear Power Plants

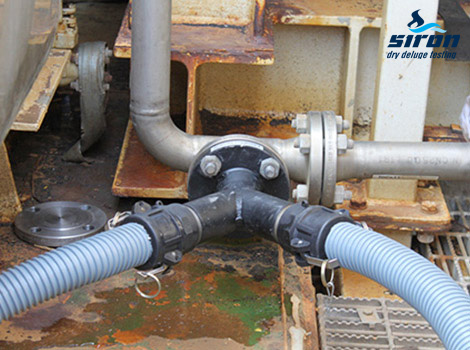

Wet deluge testing in nuclear plants is risky. SIRON Dry Deluge Testing offers safer, efficient alternatives.

Chemical Plants

Wet deluge testing disrupts chemical production. SIRON Dry Testing allows segmented testing without shutdowns.

Atria of Offices

Testing high, hard-to-reach deluge systems with water poses challenges. SIRON Dry Testing offers efficient, safe alternatives.